What causes PCB corrosion and how to clean and prevent it

Table of Contents

Printed circuit board (PCB) is the core component of modern electronic equipment, and its stability and reliability directly affect the performance of the entire system. However, during use, PCBS may suffer from corrosion. This will not only reduce the working efficiency of the circuit board, but also lead to equipment failure in serious cases.

This article will delve into the causes of PCB corrosion, and how to effectively clean and prevent corrosion to ensure the normal operation of electronic equipment.

Causes of PCB corrosion

Corrosion of printed circuit boards (PCBS) is a complex and multi-factor process. It is not only affected by the external environment, but also closely related to the material, design and manufacturing process of the circuit board itself. The following are the main causes of PCB corrosion:

1. Environmental factors

Humidity: High humidity is a common cause of PCB corrosion. The presence of water will accelerate the metal oxidation process, especially in the air containing salts or other pollutants, water molecules can act as a conductive medium, promoting the production of electrochemical corrosion.

Temperature: High temperatures also speed up the chemical reaction rate, making the corrosion process faster. In addition, the thermal expansion and contraction caused by temperature changes will also cause mechanical stress on the circuit board, which will aggravate the corrosion phenomenon.

Pollutants: Pollutants in the air, such as hydrogen sulfide, chloride, etc., can generate highly corrosive compounds after contact with the metal on the circuit board, causing rapid corrosion of the metal.

2. Chemical exposure

Acid and alkaline substances: direct contact with acidic or alkaline substances, or long-term exposure to acid and alkali gases, such as sulfur dioxide, ammonia, etc., will accelerate the corrosion of metals.

Detergent residue: Some cleaners used in the circuit board manufacturing and maintenance process, if not completely removed, the residual chemical substances will act on the circuit board for a long time, causing slow but continuous corrosion.

3. Electrochemical corrosion

Electrolyte presence: In a humid environment, the electrolyte solution on the circuit board (such as salt water, sweat, etc.) can act as a conductor to form a tiny battery, which causes electrochemical corrosion.

Potential difference between different metals: When there are different kinds of metals on the circuit board, due to the difference in electrochemical potential between them, a galvanic cell will be formed. This will accelerate the corrosion rate of the lower potential metal. This phenomenon is particularly obvious in the solder joints and joints of the circuit board.

4. Design and manufacturing defects

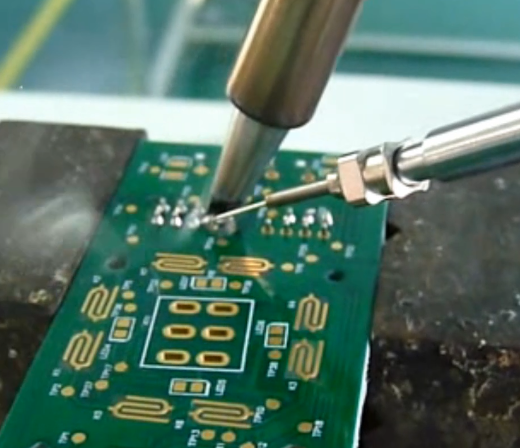

Poor welding: Defects in the welding process, such as joint holes, insufficient solder, etc., can cause local stress concentration, making the area more prone to corrosion.

Protective layer damage: If the solder mask, coating and other protective materials on the circuit board are cracked or peeled, the metal below will be exposed. This leaves the board unprotected and accelerates the corrosion process.

How to remove circuit board corrosion

Once a PCB shows signs of corrosion, timely and correct cleaning steps are essential to restore its functionality and extend its service life. The following are a series of effective ways to remove circuit board corrosion:

1. Power off and isolate safely

Before starting any cleaning operation, ensure that the circuit board is completely powered off. The circuit board should be safely isolated from the device to avoid current passing through the corroded area and prevent short circuits or other electrical failures.

2. Preliminary observation and evaluation

Use a magnifying glass or microscope to carefully examine the corrosion site of the circuit board to determine the type of corrosion (such as oxidation, electrochemical corrosion, etc.) and severity in order to choose the appropriate cleaning method.

3. Remove with a soft brush

For minor surface corrosion, use a soft brush to gently brush off corrosion products. Avoid using hard tools to prevent scratching the board surface or damaging sensitive components.

4. Clean with detergent

Isopropyl alcohol is suitable for removing oil stains and mild corrosion. Use a cotton swab to dip appropriate amount of isopropyl alcohol and gently wipe the corroded area.

For more severe corrosion, a mixture of acetic acid and hydrogen peroxide can be used. White vinegar can be mixed with 3% hydrogen peroxide in a ratio of 1:1, and the solution can be applied to the corroded area with a cotton swab. Wait a few minutes before rinsing with water.

For the green patina produced by copper corrosion, it can be cleaned with a diluted sodium carbonate solution, then thoroughly rinsed with water and dried.

5. Ultrasonic cleaning

If the corrosion is more serious, and the circuit board structure allows, you can consider using ultrasonic cleaning machines to remove stubborn corrosion products through high-frequency vibration. However, it is necessary to choose a cleaning solvent suitable for the material and components of the circuit board.

6. Dry and moisture-proof treatment

After cleaning, make sure the board is completely dry. You can use a hair dryer in a low temperature mode or place it in a well-ventilated place to air dry. For particularly sensitive circuit boards, it may be necessary to dry them in a drying oven to prevent moisture from causing corrosion again.

7. Reapply the protective layer

After cleaning, the circuit board should be re-coated with a protective layer, such as varnish or three anti-paint (waterproof, dustproof, anti-mold) to isolate air and moisture and prevent future corrosion.

How to prevent corrosion

Here is a list of proven prevention strategies, from the design stage to daily maintenance:

1. Use corrosion-resistant materials

Substrate selection: Preferred substrate with good corrosion resistance, such as FR-4 epoxy fiberglass board, which can remain stable under most environmental conditions.

Metal layer treatment: The metal layer of the circuit board is plated with a layer of corrosion-resistant metal, such as gold, silver or tin plating, which can effectively resist corrosion.

2. Design optimization

Reasonable layout: The design should take into account the heat dissipation requirements of the circuit board, avoid too dense lines near the heat source, and reduce the risk of accelerated corrosion due to temperature rise.

Isolation of sensitive areas: For areas susceptible to corrosion, such as power input, signal input and output ports, additional isolation measures should be taken, such as increasing the thickness of the protective layer.

3. Strictly control the manufacturing process

Welding quality: The temperature in the welding process should be properly controlled to avoid overheating resulting in metal oxidation. At the same time, ensure that the solder joint is full and reduce the holes and cracks.

Surface treatment: The use of high-quality surface treatment technology, such as organic Conformal Coating (Conformal Coating), three anti-paint, etc., to provide a uniform layer of protective film for the circuit board, isolating air, moisture and pollutants.

4. Environmental control

Temperature and humidity management: In the storage and working environment of the circuit board, maintain appropriate temperature and humidity to avoid extreme conditions that are too high or too low.

Pollution control: For environments that may be exposed to corrosive gases or liquids, air purification and sealing measures should be taken to reduce the impact of harmful substances on the circuit board.

5. Regular maintenance and testing

Cleaning and maintenance: Clean the circuit board regularly with a mild cleaner and a soft brush, especially those prone to dust or moisture.

Corrosion monitoring: Set up a regular corrosion monitoring plan. Use specialized inspection tools to check the corrosion of the circuit board, so that early detection of problems and timely treatment.

6. Emergency preparedness and response

Spare parts reserve: For key circuit boards, a certain number of spare parts should be reserved for emergency needs.

Emergency procedures: A detailed corrosion emergency procedures are in place to ensure prompt response and appropriate cleaning and repair measures are taken when signs of corrosion are detected.

conclusion

PCB corrosion is a complex multi-factor problem. It not only affects the performance stability of electronic equipment, but also may shorten its service life. Through the in-depth analysis of the causes of corrosion, we understand that environmental factors, material selection, manufacturing process, etc., may become the inducement of corrosion. Therefore, it is particularly important to take effective cleaning methods and preventive measures.

For electronic equipment manufacturers and maintenance personnel, the establishment of a comprehensive PCB corrosion management and maintenance system can not only improve product reliability and user satisfaction, but also save costs in the long run and enhance market competitiveness. In the future, with the continuous emergence of new materials and new technologies, we have reason to believe that PCB corrosion problems will be more effectively controlled and inject more vitality into the development of the electronics industry.