The Future Trends of PCBA Manufacturing: How TDT is Leading the Way

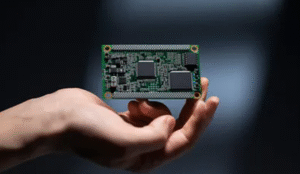

The PCBA (Printed Circuit Board Assembly) industry is undergoing rapid transformation, driven by advancements in technology, evolving customer demands, and the need for smarter, more efficient manufacturing processes.

As a leading IATF16949/ISO9001:2015/ISO13485/QC080000 certified manufacturer, Shenzhen Tianditong Electronics Co., Ltd (TDT) has been at the forefront of these changes, leveraging cutting-edge equipment, intelligent systems, and end-to-end services to stay ahead of the curve.

How to Choose the Right PCBA Manufacturer: A Comprehensive Guide

For electronics brands seeking reliable manufacturing partners, selecting the right Printed Circuit Board Assembly (PCBA) manufacturer is critical. The wrong choice can lead to costly delays, quality failures, or supply chain disruptions.

Based on industry best practices and insights from leading manufacturers like Shenzhen Tianditong Electronics (TDT), here’s a structured approach to evaluating potential partners across 9 decisive factors.

Unlocking Excellence in Electronics Manufacturing: Why Choose TDT for Your PCBA Solutions

This blog dives deep into TDT’s PCBA service advantages, production workflows, and the tangible benefits of partnering with TDT to elevate your projects.

Precision, Speed & Smarter Production: Why Global Brands Trust TDT for PCBA Manufacturing

Shenzhen Tianditong Electronics Co., Ltd (TDT) is one such leader, offering end-to-end PCBA solutions backed by advanced equipment, intelligent traceability systems, and over 20 years of expertise.

Why Shenzhen Tianditong Electronics (TDT) Stands Out as Your Premier PCBA Partner

In an era where electronics complexity and sustainability demands escalate, TDT offers more than PCBA—we deliver innovation, accountability, and agility. Whether you’re prototyping a IoT device or scaling automotive production, our team is ready to elevate your project.

The role of heat pads on printed circuit boards

With the continuous progress of science and technology, the functions of electronic products are increasingly complex, and the integration degree is constantly improving. This requires the Printed Circuit Board (PCB) not only to achieve more functions in a limited space, but also to ensure good performance and reliability. Thermal management is one of the key factors to ensure the long-term stable operation of electronic products. The Thermal Pad, as a member of the thermal management system, plays a crucial role in PCB design.