Everything you need to know about PCB functional testing

Table of Contents

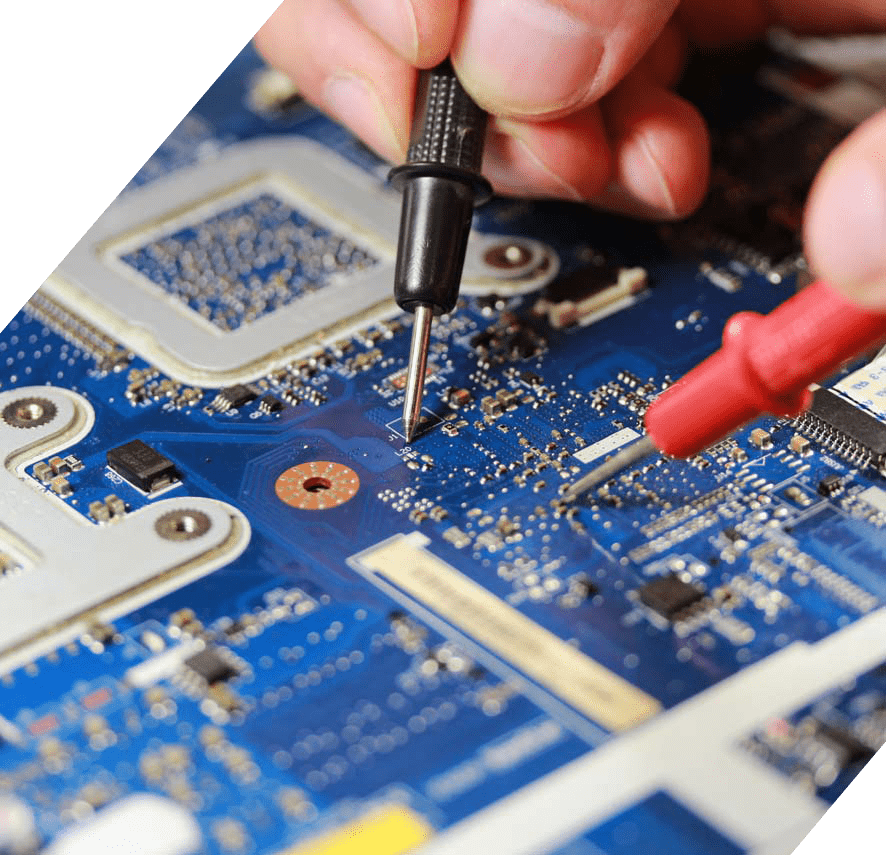

In today's rapidly developing electronic age, the outstanding performance of every smart device is inseparable from a carefully crafted printed circuit board (PCB). Although they are silent, they are high-speed channels of information transmission, carrying the hope of scientific and technological advancement. However, excellence is not an accident, but the result of countless tests and optimizations. Today, let's dive into the core of PCB manufacturing and reveal functional testing.

What is PCB Functional Testing?

PCB functional testing is a quality control means to verify all or part of the circuit function on the circuit board by simulating actual working conditions.

Imagine, if your phone or computer is a human body, then the printed circuit board (PCB) is like a nervous system throughout the body, responsible for transmitting various information and instructions. The PCB functional test is like giving the "electronic friend" a comprehensive physical examination to check whether its "nervous system" is unimpeded and can complete various tasks accurately. This process is not just to see if the wiring is properly connected, but more like letting the circuit board run in a virtual working environment. See if it is fast and accurate when receiving signals and processing information, and whether it is tacit with other electronic parts. In this way, we can ensure that the electronics in your hands are smart and reliable, and will not easily "get sick."

Common PCB functional test methods

There are several common PCB functional test methods, each of which is a key step in ensuring the reliability of electronic equipment:

1. Power-On Test (Power-on Test)

This is the most basic functional verification. By powering the PCB, observe whether the circuit board can start normally and whether the basic functions are running smoothly. Testers monitor power management, basic signal paths, and the response of key components to confirm that there are no startup failures or abnormal behavior.

2. Automated testing

In-Circuit Test (ICT) : The use of automated test equipment, through the special probe contact the test point on the circuit board, the electrical parameters of the circuit accurate measurement, quickly identify component failure, open or short circuit.

Flying Probe Test: The automated system uses a movable probe that dynamically contacts the test point according to a preset program. This method is suitable for flexible testing of small batches or complex PCBS without the need for custom fixtures.

Automated Optical Inspection (AOI) : The use of high-resolution cameras to capture PCB images. Image processing software is used to analyze the appearance quality of solder joints, component positions, etc., to achieve efficient and objective detection.

3. System function test

Verify the PCB's ability to interact with external devices under conditions that simulate the actual operating environment, including advanced functions such as signal processing, data transfer rate, and software compatibility. This usually requires writing specific test software to trigger and monitor the various operating modes of the PCB.

4. Boundary scan test

Using the boundary scan function of the integrated circuit, the digital logic on the circuit board is tested in depth through standardized interfaces such as JTAG. This method does not require direct access to each pin and is particularly suitable for complex digital circuits and fault diagnosis.

5. Stress test and aging test

The PCB is tested under extreme or long-term operating conditions to assess its ability to maintain stable operation in harsh environments such as high temperature, high humidity, and voltage fluctuations to ensure long-term reliability and durability.

The comprehensive application of these test methods builds a three-dimensional test system. It not only raises the quality threshold of PCB, but also accelerates the positioning and solution of the problem, providing a solid guarantee for the stability and safety of electronic products.

Why do functional testing?

Here are some core reasons to do functional testing:

1. Ensure product performance and reliability

Through functional testing, you can verify whether the performance of the PCB under actual working conditions meets the design standards, and ensure that the signal processing, power transmission, logic control and other functions of the circuit can be accurately executed. This is directly related to the stability of the end product and the user experience.

2. Early fault detection and prevention

Performing functional testing before product assembly and delivery allows early detection of potential defects, such as component failures, poor welds, or design errors. This prevents these problematic products from flowing to the market and reduces the risk of customer complaints and product recalls.

3. Optimize production process and cost control

Functional testing helps identify weak links in the manufacturing process, prompting companies to continuously improve the production process, reduce the generation of defective products, and reduce rework and maintenance costs. In the long run, it can significantly improve productivity and economic efficiency.

4. Design verification and feedback

Test results are not only a part of quality control, but also an important basis for design iteration. Through the analysis of the test data, the design team can obtain valuable feedback that can be used to optimize the circuit design and improve the performance and reliability of subsequent products.

5. Meet industry standards and compliance

Many industries, especially in the fields of aerospace, medical equipment and automotive electronics, have strict specifications and certification requirements for PCB quality. Functional testing is the basis for meeting these standards and obtaining the relevant certifications, ensuring the product's entry into the global market.

6. Enhance brand reputation and competitiveness

High-quality products are the cornerstone of corporate reputation and brand value. Through rigorous functional testing, enterprises can provide more reliable products, enhance consumer confidence, and thus stand out in the fierce market competition.

The flow of functional testing

In order to ensure the comprehensiveness and validity of the test, the following procedures are generally followed:

1. Requirement analysis and test plan development

First, according to product specifications and design requirements, clear test purpose, scope, standards and acceptance criteria. Then develop a detailed test plan, including test items, test sequence, required resources, and expected completion time.

2. Test fixture and program design

Design or select the appropriate test fixture to ensure that each test point can be accurately reached. At the same time, write the test program, define the test steps, expected results and judgment logic. For automated testing, the corresponding test software needs to be developed or configured.

3. Test preparation

Prepare the test environment according to the test plan, including setting up test equipment, calibrating instruments, and installing necessary software. Train testers to ensure they are familiar with the test process and practice.

4. Preliminary testing and debugging

Perform initial tests on small batches or samples to verify the suitability of the test fixture and the accuracy of the test procedure. Adjust test Settings for identified problems to eliminate false positives and missed tests.

5. Test execution

Load the PCB board into the test system and perform the tests in turn according to the test plan. Collect test data and record test results, including pass, fail and any abnormal conditions.

6. Result analysis and fault diagnosis

Analyze test data, compare expected results, and conduct in-depth analysis of failed test items. Use fault diagnosis tools and methods to locate the cause of the problem.

7. Repair and retest

Repair or replace unqualified PCBS based on diagnostic results. After the fix is complete, run the functional test again to ensure that all issues have been properly resolved.

8. Test report and feedback

Summarize test results and generate detailed test reports, including test overview, pass rate, failure analysis and recommendations. Feedback testing to design and production for product improvement and process optimization.

Application of functional testing

PCB functional testing has a wide range of applications, covering almost all industry areas that rely on electronic components. The following are detailed descriptions of several typical application areas of functional testing.

1. Consumer electronics

In consumer electronics such as smartphones, tablets, and smart home devices, functional testing ensures the accuracy of functions such as high-speed data transmission, power management, and display drivers of the circuit board, enhancing the user experience.

2. Communications industry

From base stations to routers to satellite communications equipment, functional testing is a necessary step to verify key indicators such as signal processing, data exchange, and RF performance, ensuring the stability and reliability of communication systems.

3. Automotive electronics

In the driver assistance system, navigation and entertainment information system of automobile, functional testing is very important to ensure the stable work of electronic module in complex environment, which is directly related to driving safety.

4. Medical equipment

From electrocardiogram machines to ventilators, PCB functional testing of medical devices ensures highly accurate signal acquisition, processing and control functions, which is the basis for patient safety and treatment effectiveness.

5. Aerospace

In avionics, satellite and missile guidance systems, the precision and rigor of functional testing is at the highest level, ensuring stability and reliability in extreme environments with no margin for error.

6. Military and defence

In military applications such as radar systems, communications equipment, and navigation equipment, functional testing is essential to ensure equipment concealment, anti-interference, and instantaneous response, and is directly related to national security.

7. Industrial control and automation

In industrial robots, automated production lines, intelligent sensors and other applications, functional testing ensures the precise control and efficient operation of the control system, improving production efficiency and safety.

8. New energy and electricity

In solar inverters, electric vehicle battery management systems, and smart grid equipment, functional tests validate the stability and efficiency of circuit boards under high voltage and high current conditions, driving the development of clean energy technologies.

PCB functional testing challenges

Although PCB functional testing is a key step to ensure the quality of electronic products, it faces many challenges in practical applications. These challenges challenge the innovation and optimization of test technology. Here are some of the main challenges of PCB functional testing.

1. Increased complexity

With the diversification and integration of electronic products, PCB designs are becoming more complex, containing more layers, smaller spacing and higher density components. This puts forward higher requirements for test probe accuracy, test coverage and test time.

2. Test cost control

With the increase of test complexity, the development cost and maintenance cost of test equipment and fixture also increase. How to control test cost reasonably while ensuring test quality becomes a problem that enterprises must face.

3. Balance of test coverage and efficiency

Achieving 100% test coverage is ideal but difficult, especially in mass production. How to design a test solution that is efficient and covers key test points within limited time and cost is a big challenge.

4. Adaptability of new technologies

Emerging technologies such as flexible PCBS, embedded components, and three-dimensional packaging technologies pose challenges to traditional testing methods. This requires the development of new testing strategies and techniques to adapt to these changes.

5. Automation and intelligence requirements

In order to improve the efficiency and accuracy of testing, automated and intelligent testing has become a trend. However, to achieve this goal, technical obstacles such as software development, application of machine learning algorithms, and system integration need to be overcome.

6. Environmental adaptability test

In some applications, such as aerospace, military, automotive, etc., PCBS need to work in extreme temperatures, humidity, vibration and other environments. Simulating these conditions for functional testing is a major challenge for the construction of test equipment and test environments.

conclusion

In short, PCB functional testing is an indispensable part of the electronic manufacturing industry chain, which is not only related to the performance of a single product, but also affects the innovation and development of the entire industry. From consumer electronics and communications equipment to aerospace and medical equipment, any industry that relies on PCBS is inseparable from functional testing. In the face of increasing complexity and market demand, continuous optimization of test technology and improvement of test automation will be an important trend in the field of PCB functional testing in the future.